CREATING A CIRCULAR PRODUCT WITH JOHN COTTON GROUP LTD.

Case Study – ProcureCircular

Jordanna Marshall

Founder, Managing Director

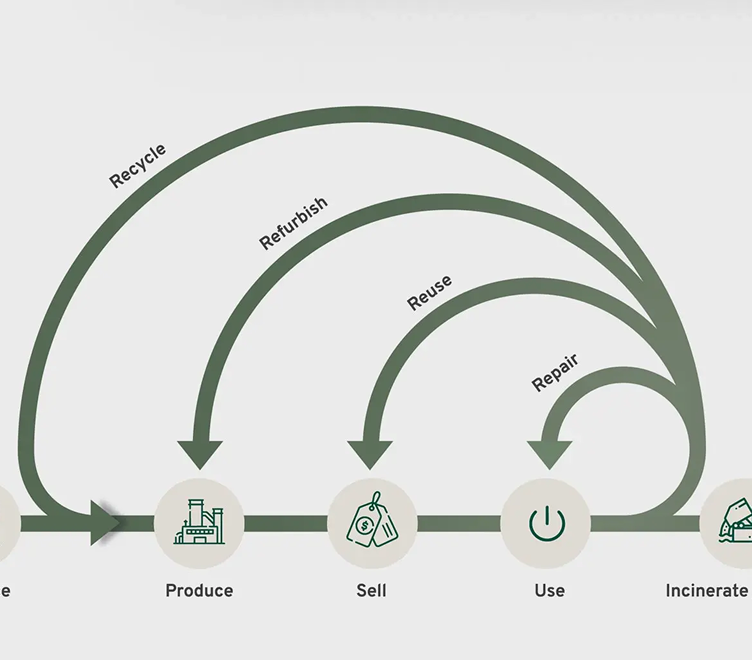

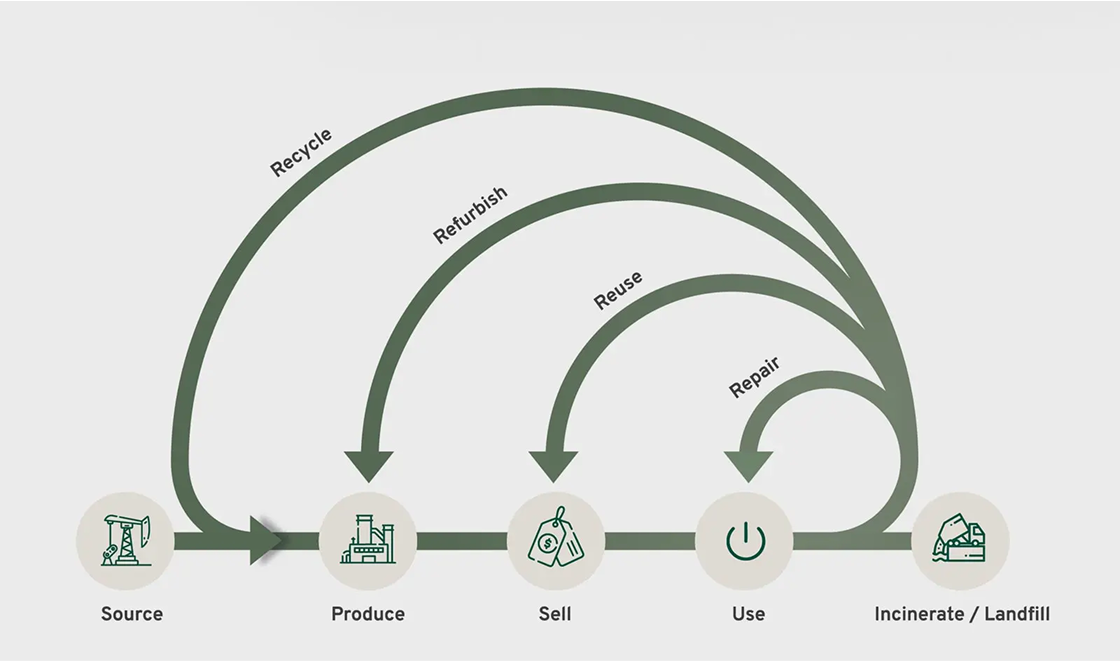

WHAT IS A CIRCULAR PRODUCT?

A circular product is a product that is designed and produced within the circular economy principles. This means that the capabilities of repair, reuse, refurbishment, and recycling at the end of life, are built into the design and production process of a circular product, alongside an emphasis on using natural materials which can ultimately cycle back into the earth as bio feedstock.

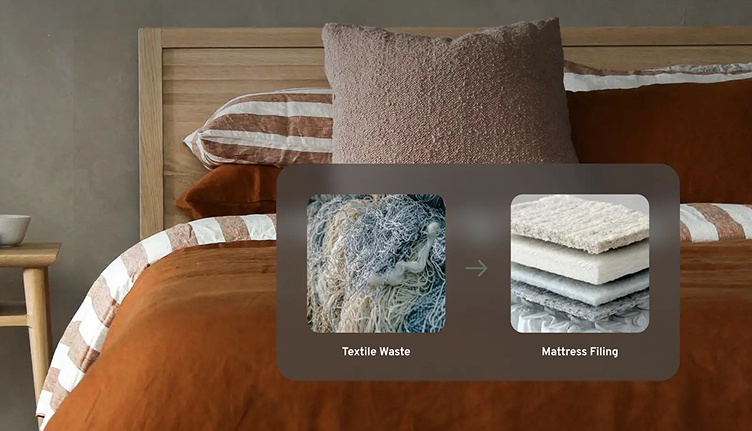

JOHN COTTON NONWOVENS MATTRESS Fillings

Circular principles designed into John Cotton Nonwovens mattress filings:

- John Cotton Nonwovens manufacture circular mattresses imbedding the principles of the circular economy across their product ranges.

- The materials used in John Cotton Nonwovens mattress production are either off-cut waste from their manufacturing processes or purchased waste materials such as selvedge. Both these waste streams would otherwise go into landfill. Instead they are given a second life by being designed into creating a new circular mattress, rather than going to landfill.

- The mattresses are 100% recyclable at end of life, continuing the circularity of the materials in ongoing cycles of material re-use.

John Cotton Nonwovens currently recycle around 1/2million reclaimed garments per week, plus the equivalent of 25,000 pairs of jeans, which are manufactured back into creating their products, such as mattresses. This helps John Cotton Nonwovens to operate on a ‘zero to landfill' basis, with all textile waste being recycled back into production.

JOHN COTTON NONWOVENS IN COLLABORATION WITH PROCURECIRCULAR

John Cotton Nonwovens sources an est 200,000 tonnes per annum of selvedge annually to create its circular products. Selvedge is the tightly woven edges of fabric, which are denser and sturdier than the main fabric. Traditionally these are cut off during production processes and dumped as waste in landfill.

To facilitate creating circular products, ProcureCircular provides access to these waste materials for businesses. Through their B2B SaaS platform they enable the exchange between businesses who want to avoid putting their textile waste in landfill inorder to create circularity within their production processes, and those businesses looking to design circular products through reusing waste materials.

AMBIO-N’s mission is to accelerate access to materials that improve the environmental footprint of end-products and create a higher sustainable footprint across the textile industry.

INSULATED PACKAGING

John Cotton Nonwovens produce insulated liners and pouches from a range of waste textiles. The company collects and source waste such as denim selvedge, recycled plastic waste like polyester bottles, and natural textile alternatives such as cotton and wool.

This is then used to create the insulating layer within the packaging, which is encased inside a polyethylene bag, which is recyclable in most household council bins.

John Cotton Nonwovens are creating a fully circular product by using waste materials, to create

a product that can then be fully recycled at its end of life, thereby minimising its impact on the

environment.

Production Process

Creating a circular product requires circular economy principles to be built into the design of the product as well as into the production process, with an emphasis on using renewable energies.

The key principles of creating a circular production process focus on

John Cotton Nonwovens is applying such principles in the creation and production of its

mattress filing and insulated packaging products

John Cotton Nonwovens is applying such principles in the creation and production of its

mattress filing and insulated packaging products

- Using textile waste selvedge to create the insulator pads and internal filings.

- Reusing any offcuts from the production process to feed back into the product design as material inputs.

- Using natural and biodegradable fibers, such as wool, hemp, and bamboo, to create filing layers. All materials biodegrade at end of life and feed back into natural systems.

- Synthetics used are currently 60% made from recycled plastic waste.

- All products are 100% recyclable at the end of life, creating a circular process that designs beyond the lifespan of the product.